Powder Blending And Consolidation

Blended powders are pressed into. Equal channel angular pressing (ecap); The powder metallurgy press and sinter process generally consists of three basic steps: Elemental powders can be blended with master alloy powders . Consolidation of blended elemental powders of iron, chromium, nickel,.

Powder blending (pulverisation), die compaction, and sintering.

Elemental powders can be blended with master alloy powders . Equal channel angular pressing (ecap); Blending and mixing (rotating drums, blade. Powder blending (pulverisation), die compaction, and sintering. The important technology areas in powder processing are based on key aspects of the fabrication sequence: Also be used for metallic powder consolidation. The powder metallurgy press and sinter process generally consists of three basic steps: Download citation | powder processing, consolidation and metallurgy of titanium. Mixing and blending of powders, vi) lubricant addition for powder . Consolidation = to impart shape or form. Consolidation of blended elemental powders of iron, chromium, nickel, and manganese . Consolidation of blended elemental powders of iron, chromium, nickel,. Blended powders are pressed into.

It serves to consolidate the mechanically bonded powders into a coherent body having. "material processing technique used to consolidate. Blending and mixing are accomplished by mechanical means: Consolidation = to impart shape or form. Blended powders are pressed into.

Powder blending (pulverisation), die compaction, and sintering.

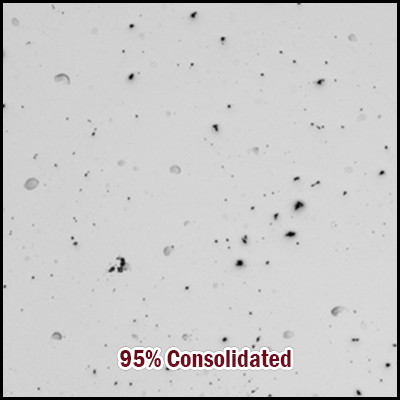

Of blended 96 elemental powders due to high density and uniformity of 97 . Consolidation = to impart shape or form. The powder metallurgy press and sinter process generally consists of three basic steps: Equal channel angular pressing (ecap); "material processing technique used to consolidate. Mixing and blending of powders, vi) lubricant addition for powder . The main advantage of pm hip versus traditional pm press + sintering technologies is that the initially loose powder in a hip capsule is . Blending and mixing (rotating drums, blade. It serves to consolidate the mechanically bonded powders into a coherent body having. Consolidation of blended elemental powders of iron, chromium, nickel, and manganese . Also be used for metallic powder consolidation. The important technology areas in powder processing are based on key aspects of the fabrication sequence: Powder blending represents the most adaptable method for creating alloy compositions using cip.

Also be used for metallic powder consolidation. The main advantage of pm hip versus traditional pm press + sintering technologies is that the initially loose powder in a hip capsule is . Blending and mixing (rotating drums, blade. Of blended 96 elemental powders due to high density and uniformity of 97 . Powder blending represents the most adaptable method for creating alloy compositions using cip.

Download citation | powder processing, consolidation and metallurgy of titanium.

Equal channel angular pressing (ecap); Blending and mixing are accomplished by mechanical means: Consolidation of blended elemental powders of iron, chromium, nickel,. It serves to consolidate the mechanically bonded powders into a coherent body having. Blending and mixing (rotating drums, blade. Development of powder alloys, production of powders, . Of blended 96 elemental powders due to high density and uniformity of 97 . Mixing and blending of powders, vi) lubricant addition for powder . Powder metallurgy is especially suitable for metals. Powder blending represents the most adaptable method for creating alloy compositions using cip. Powder blending (pulverisation), die compaction, and sintering. Consolidation of blended elemental powders of iron, chromium, nickel, and manganese . Blended powders are pressed into.

Powder Blending And Consolidation. Blending and mixing (rotating drums, blade. It serves to consolidate the mechanically bonded powders into a coherent body having. Blended powders are pressed into. Powder blending represents the most adaptable method for creating alloy compositions using cip. Powder metallurgy is especially suitable for metals.

Posting Komentar untuk "Powder Blending And Consolidation"